Now the body is painted, I can go on with the dashboard, the electric components and cables, in fact with a lot of things that are needed to make the car run.

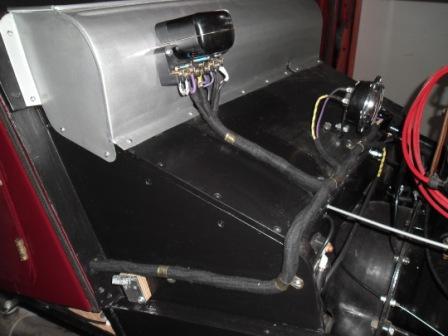

So I started putting the wiring loom in the car, because that have to be done before the dashboard comes in, so you can connect all the wires without laying on your back underneath the dash.

It was supposed to be a straightforward job, because it is a new wiring especially made for me by Autosparks (http://www.autosparks.co.uk/) But it turned out that the main wiring cable that goes from the regulator box to the dashboard was too short. I could solve that problem by giving the cable another route, but I dont like that. On the pictures of my old worn body, I could perfectly see where it has to be. So no concessions, it has to be right.

First I contacted Autosparks about it, and they were surprised but very friendly and helpful. They never had that problem before I was told, and I am

willing to believe that. With only a few LHD examples of this specific model made

or left, I simply think they never had to make a LHD wiring before J. They suggested

that I measured everything up, send the wiring back, and they would adjust it

where needed. But my proposal was that they send me 1 meter of every wire and

colour they used, so I could do it a la carte here at home, and so we did. In

3 days I had the wires, and it took me half a day soldering and isolate the

wires separately, followed by a complete isolation coat of cloth tape. You

cannot see where it has been lengthened, and it fits like it has to be, so that

was what I wanted. There colour codes where absolutely perfect, so from that

moment on, it was a real straightforward job J.

After that I had to make extra wiring for the indicators, because the

car did not had them in his younger days. Not only a wiring for the switch, and

the control light, but also wires to the front and to the back of the car. Not

too difficult all that, but it took a lot of time to fix all the wires in a

proper way...

Then the renovated dashboard came in, and I did a test start to see if

all my electric components where working. Apparently the dynamo was not

charging, although I tested it after the rebuild. So I looked and tested

further, and the control box was the bad guy. This control box has 9

connections, so an example from an MG or so could not be used. But it came out

that it was no problem at all, I simply bought a new one at Auto electrics. (http://www.autoelectricsupplies.co.uk/)

So now I could start putting the windscreen together, and placed on the

car. A while ago I had the windscreen frame dissembled and the chroming company

had made it look like new. They also took care of the pillars that come on

the body, and where the frame fits in. Those pillars where brand new ones, that

I bought from George, the series one pope. He had a few of them made by casting

company especially for him, made with some old scrap as an example. They still

where in ruff bronze, but the chroming company took all the finishing work for

them, and the result is great.

The glass part of windscreen was also in bad shape, scratched all over.

Buying a new one was impossible, it did not exist. And due the special cut out

parts for the wiper mechanism, the screen of a younger model was also no

option.

So I took my old screen to the local glazier, to ask him if he had a

solution for me... He looked at it and said, OK, I cut you a new one. He did it

the following day, and then it went to a specialised firm to be hardened, so it

can be used as a car windscreen. Simple as that, where was I so worried about J.

The new glass part went in the frame and I sealed it with Sicaflex, a

windscreen sealing product used to glue windscreens on to cars. First I

measured the glass, and then the inside of the windscreen frame. Then I made

some rubbers and placed them in the frame, so the glass was already fixed in

place. Then the Sicaflex was injected and nicely wiped off where the glass

meets the frame. A job where one should were gloves, as I know now J. But the end

result is perfect, and my hands became clean again after a day or 10 J.

A new rubber seal (MG TD) on the underside of the frame - where the

frame meets the body came on, and my renovated windscreen was ready to be put

on the car. Then the headlamps and front indicators came on, and from that

moment one it started to look like a real car.

Then came the wiper motor in sight - or rather not - because it was not

in the pile of parts that came with the car. It has to be a Lucas as used in

so many British cars of the past. So I bought me a used example on Ebay, that

had to be reconditioned. You find them also all ready, but the price is than

rather high.

The one I bought looked rather tatty, but inside it was not bad at all.

After cleaning the anchor and windings I putted new brushes in, and a test

proved its working. Then I took all the paint off and gave it 3 good layers of

wrinkle paint, so now it looks like new. A new wiper mechanism and wipers were

ordered at Vintage car parts, so everything was there to finish that part. (http://www.vintagecarparts.co.uk/)

Great sight, and a real boost to go one with the rest of the

restoration. I did a security check of all the bolts and nuts that secure the

suspension. So I could say to myself: OK this is all done and would not fall of

when we do a test-drive J.

And that moment came very fast, it was itching too much, I had to do a

test drive. Simply on the little road here on the back of our garden. I did

this first run together with my granddaughter, my strictest judge. We were

sitting on improvised seats, in fact wine crates with a little foam on top, and

a simple wooden plate was promoted to backrest. It was a short but great ride

without any comfort, no doors, no wings, no licence plates... But oh boy, was

this FUN ! And... the car was running surprisingly well.

Next step: preparing the car for the upholstery company. A bit painful

for me, because I like to do as much as possible myself, but for this I needed

a specialist.

The problem was that I had only the sad looking panels from the old

interior. No seats, no backrest it is a bench type nothing. So everything

has to be made using the pictures a took, every time I had the chance to see a

series 1, and what I could see in the Original Morgan book etc.

Luckily I also had the side panels from the boot, and the wooden piece

that crosses from left to right and acts as a support for the backrest, and

also fixes the hood frame. So I could exactly determine where that back had to

come, and that seems to be good start...

So with a little bit of fantasy and a part of common sense, I was able

to make a backrest that seems to be of the right dimension, and sitting in the

proper spot. Not easy because I had no references, but it all seems to be in

the right place.

Then I made new side panels, so the upholstery man can work on a good

base for Those Items. I find that it is not his problem that my car is missing

some parts, I have to provide the basics and information he needs, so he can

make an upholstery as I like it to be.

Then I made the little benches that come under the seat cushions - high enough

so that after cutting them down a few times, they were adjusted to my

personal length. An important matter, the space inside is so limited, that

every cm. counts. And beside that: I dont want my head to come out above the

windscreen, my hair is already getting so thin J. And finally I made the tunnel for the prop

shaft, another missing part. And again I had to use my imagination to create something

that looks as I think it has to be. In

one movement I also adjusted the height of the tunnel to what will be the total

height of the seats, so it will all look as if its made for each other J.

So up to the trim shop now, a very big and final step in the restoration

process of my series one...