|

Founded in 1973 in its current structure, the COSC is a

not-for-profit association. It was created by five watch making cantons (Bern,

Geneva, Neuchâtel, Solothurn and Vaud) as well as the Federation of the Swiss

Watch Industry. It encompasses the laboratories that had been established

independently of each other from the late 19th century onwards.

Its goal is to:

Measure and test the precision of watch

and clocks movements in order to grant them official chronometer status.

Promote the chronometer and undertake any legal action aimed at defending and

protecting this title internationally.

The COSC does not manufacture chronometers; it merely certifies that the

watchmakers have provided this high value added for their products and attests

that they may justifiably claim this prestigious title. The BOs (short for

"Bureaux Officiels de Contrôle de la marche des montres" - meaning

Official Watch Rating Centres) currently constitute the three laboratories

within the COSC.

Located in Bienne, Geneva and Le Locle, their mission is to test the movements

submitted by manufacturers. They have each earned individual accreditation as SCS (Swiss

Calibration Service) laboratories from SAS (Swiss Accreditation Service).

The

three BOs work with state-of-the-art equipment developed in-house by the COSC

engineers. The specific requirements are such that all the BO instruments have

had to be custom-made, since nothing equivalent exists on the instrument

market. The COSC management, based in La Chaux-de-Fonds, coordinates the

operation of the BOs and provides them with the measurement and result

management equipment, as well as ensuring maintenance. It establishes the

testing prescriptions applicable to the various types of movement submitted, it

develops the equipment and measurement methods for the BOs and undertakes any

necessary action in matters relating to marketing, communication and defense of

the chronometer in the broadest sense of the term.

The future of the COSC is closely entwined

with that of the submitting producers and the evolution of their needs. While

the responsibility of the COSC is to tirelessly improve its productivity and

above all the precision of its testing methods, it must also play a determining

role in watchmakers ongoing quest to develop ever more efficient products. It thereby ensures that the precision one must

expect from a modern chronometer is consistent with the state of the art in

terms of high-end watch production.

The COSC must maintain constant contact with

its partners. Thanks to its rigorous standards, objectiveness and neutrality,

it serves as the guarantor of the voluntary determination to achieve precision

and excellence stemming directly from the producers themselves.

The term chronometer is often wrongly

applied to timekeeping instruments fitted with an additional mechanism that may

be set in motion by pushbuttons to enable measurement of the duration of an

event. Such an instrument is in fact a chronograph or chronoscope. It may of

course be chronometer-certified, provided it meets the criteria set for the

standard. In its technical regulations, the COSC has included an additional

condition, namely the permanent display of the seconds.

So a chronometer is in fact high-precision

watch capable of displaying the seconds and housing a movement that has been

tested over several days, in different positions and at different temperatures,

by an official neutral body (COSC). Each

chronometer is unique, identified by a number engraved on its movement and a

certification number given by the COSC. Each movement is individually tested

for several consecutive days, in 5 positions and at 3 temperatures. Each

movement is individually measured. Any watch with the denomination

"chronometer" is provided with a certified movement.

The

test for mechanical watches

ISO 3159 provides the definition of a

wrist-chronometer with spring balance oscillator. Only movements which meet the

precision criteria established under ISO 3159 are granted an official

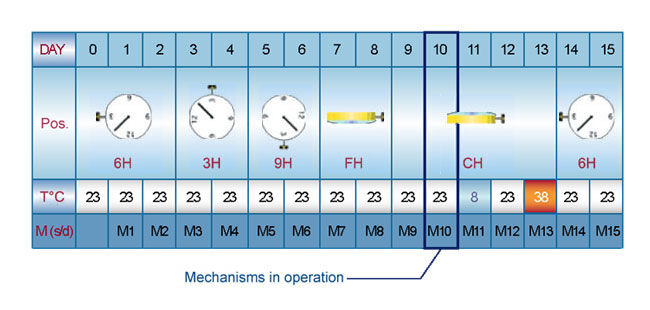

chronometer certificate. Movements are tested for 16 consecutive days according

to a tests panel.

Every day, including Saturdays and

Sundays, movements are measured and rewound.

Based on these measurements, 7 eliminatory criteria are calculated.

If and only if all these criteria are met, the movement is duly

"chronometer-certified".

The

test for quartz watches

No international standard has so far been

issued regarding electronic quartz watches. Based on ISO 3159, the COSC has

drawn up a set of testing prescriptions applicable to quartz chronometers which

govern their performances in the same way as for mechanical chronometers. Taking

account of the specific technological characteristics of these products, the

COSC has adapted the tests and precision requirements. This called for the

development of special quartz movements in order to meet these new

requirements. It has become compulsory for them to be equipped with an

electronic system compensating for the variation in the frequency of the quartz

according to changes in temperature.

A new-generation quartz chronometer is

therefore 10 times more accurate than a conventional quartz watch. Moreover it

is a very exclusive product manufactured on a low scale. Each quartz

chronometer is tested for 11 days, in one position and at 3 temperatures.

The Watch Aficionado

Categorie:Attestations

|