|

The watch making

process consist of various stages. Here you find an example of what a watch

goes trough at IWC. Like so many things, a philosophy is needed first in order

to create something beautiful.

IWCs philosophy

From the

very beginning, this unusual geographical location has fostered IWCs

philosophy, which is based on a passion for watchmaking, untiring enterprise

and perfect craftsmanship. As an international premium brand name, the company

has consciously chosen to specialise in innovative mechanical watches. The

individual who purchases an IWC watch expects not only precision, functional

design and a long service life but also the kind of advanced technical features

that only a few watch manufacturers worldwide are able to provide. The

reputation of the brand from Schaffhausen is founded not least on the fact that

its highly qualified employees master every step of the production processes

behind complications like the minute repeater, the power reserve, the

tourbillon and the perpetual calendar. Behind the claim to excellence, Probus

Scafusia, which was first formulated in 1903 and stands for good, solid

craftsmanship from Schaffhausen, lies the desire to manufacture precision

timepieces that will be a joy to use and will retain their value well into the

future.

- IWCS Philosophy is based on a passion for watchmaking, untiring

enterprise and perfect CRAFTSMANSHIP

For the

designers and construction specialists at IWC, this is not only an enormous

challenge but also the force that drives them on to greater things. Every IWC

watch is professionally finished by masters of their trade. For they are the

individuals whose trained eyes, nimble fingers and precision instruments put

together IWC watches from a collection of single parts: each a fascinating

example of meticulous workmanship, functionality and design, each an

outstanding piece of engineering excellence at its very best.

Development

Whenever

IWC starts developing a new model, one question needs to be asked. What,

exactly, do the designers and construction specialists wish to achieve? Should

the watch set new standards in complexity? Will its main strength be the power

reserve, or perhaps its water-resistance? In an initial step, the first

components are modelled using computer aided design. Here, IWC attaches

enormous importance to integrating the work of construction and design with

modern production technology. Working closely with the construction engineers,

the watch designers play a crucial role in determining how best to harmonize

form and function. The dial and the strap or bracelet, the positioning of the

displays, the choice of materials and colours or the surface finish are always

the logical outcome of constructive teamwork. Apart from the technological

achievement and an attractive design, other, more emotional, aspects such as

the way the watch actually feels in the hand also play an important role.

Thus, the feel of the edge of the case, the way a push-button is activated or

the sound of the crown as it engages are not left to chance. Often, the

construction engineers and designers will take their inspiration from old

drawings. Ultimately, it is respect for the watch making pioneers of the past

that guarantees continuity at the Schaffhausen based company.

- It is respect for the

watchmaking pioneers of the past that guarantees continuity

Thanks to a

sophisticated development and quality management system backed by an exacting inspection

and testing program, IWC is able to guarantee quality of the highest order. The

advanced scientific methods used include three-dimensional computer simulations,

X-ray-based materials analyses or tests designed to show how the watches behave

under extreme practical, everyday conditions. The use of high-speed cameras and

laser measuring instruments make even the tiniest movements visible, and

sophisticated computer programs calculate exactly what stresses a part will

tolerate.

Details

such as seals, push-buttons, wheels, levers, shafts, tooth profiles or the

dimensions of springs are examined for possible sources of error from the

earliest phases of development. IWC calls this process error source analysis.

At the same time, the developers make the design reliable and service-friendly,

while ensuring that an IWC watch will continue to run and can be repaired for

many, many years.

Tests

Q. This term is used to describe a program of around thirty grueling tests

lasting several months which are designed for new watches at the prototype

phase or later as part of the approval process for the pilot series. These

tests simulate in condensed form just about everything that can happen to a

watch, under normal and extreme circumstances, during the course of its long

life. Only when several prototypes have passed stringent testing and a pilot

run has revealed no more problems is the company ready to go into series

manufacture, there by adding another fascinating chapter to the legend that is

IWC.

During

impact testing, the watch is exposed to various rates of acceleration. Normal

acceleration, due to gravity, is 1 g = 9.81 m/s². If a force of 100 g is exerted

on a watch with a case weighing 100 grams, the watchs components are subjected

for a short time to forces equivalent to 10 kilograms. The Pilots Watches from

IWC have even withstood forces of 30 g for periods of several minutes in a centrifugal

accelerator. In a pendulum impact tester, the watch is accelerated to 5,000 g

in split seconds, which simulates the effect of a free fall onto a hard wooden

floor from a height of 1 meter. One of the most demanding tests of them all is

the chapuis extrême: here, the watch is shaken around inside a small

container for hours on end, subject to knocks and impacts from all sides

140,000 at a simulated 25 g, 94,000 at 100 g and 960 at 500 g.

For test

purposes, some parts are manufactured as early as the design phase in order to

check the minimum requirements for those components subjected to unusually high

wear and tear. Take the Aquatimers rotating bezel, for instance, which

undergoes a fatigue test equivalent to four dives per day, guaranteeing a minimum

service life of 10 years.

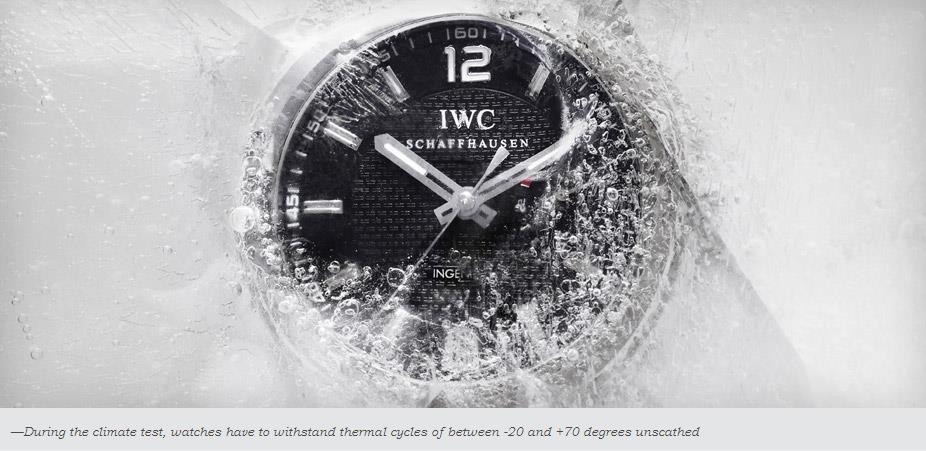

In the

climate tests, the entire spectrum of thermal conditions a watch owner can be

exposed to are systematically tested. Geographically speaking, this embraces

everything from Alaska to the Sahara and the Brazilian rainforest. Watches are

placed in a test chamber where, over a period of days and sometimes weeks, they

have to withstand temperature changes from 20 to +70 degrees Celsius and up to

95 percent relative humidity. The next item on the agenda after this ordeal is

long-term monitoring of the rate. This test makes use of an automatic

multilevel microphone to check the regularity of the beat.

A two-week

test in a saline bath at 37 degrees Celsius ensures that only materials are

selected that will not corrode in daily use or even aggressive salt water. The

rotating bezels in IWC divers watches also have to prove their reliability in

dirty water. Glasses and dials are exposed to strong ultraviolet light for days

on end and must not show any change of colour. Test schedules carried out in

the laboratory, of course, cannot successfully simulate every situation likely

to be encountered in real life. This is the reason why all new models are given

to individuals both inside and outside the company who wear them normally under

everyday conditions. Effectively, and depending on the model in question, IWC

watches are put through their paces when the wearer is chopping wood, diving,

playing golf and mountain biking, or climbing at 3,000 meters.

Assembly

In the

course of components production, the various blanks are machined with the help

of CNC milling machines. After surface machining, the acceptable tolerance for

components, in general, is just +/ 0.02 millimeters, but in certain cases this

may be as low as +/ 0.002 millimetres. After machining, the parts are finished

by hand or proceed to an electric discharge machine. CNC wire electric

discharge machines are used primarily for parts in the movement. The surface

roughness can be controlled to a tolerance of 0.005 millimeters, but for

precision EDM work, it is as low as 0.001 millimetres.

The

assembly of a movement can be divided into four distinct stages: the winding

mechanism, the going train, the escapement and the actual timing. Depending on

the model in question, it will also involve the automatic winding and

chronograph mechanisms as well as the calendar and hour counter. The most

complex of these jobs is adjusting the escapement and aligning the balance

spring so that it runs true and flat: this is a high-precision manual task that

no machine could ever carry out to remotely the same high-quality standards.

Functions and precision adjustments are checked and corrected continuously at

every stage of the assembly process. After this, highly skilled watchmakers in

the special features department add on complications such as the perpetual

calendar, split-seconds mechanism and tourbillon to the basic movement. Those

movements with a minute repeater are assembled here from the bottom up.

- After the function controls,

precision craftsmanship brings the surfaces up to IWC standard

In terms of

the precision and effort involved, the manufacture of the case is in no way

inferior to the other stages in production. For platinum cases, two blanks are

cut from a 1-kilogramme block of the metal using an electric wire discharge

machine. For watches made of precious metal, the case parts are bought in as

cast components or, for stainless-steel and titanium cases, supplied in bar

form and then machined on CNC lathes and milling machines. The maximum

permissible circularity error of the parts must not exceed 0.03 millimetres.

Milling machines are used to cut the lugs for the strap or bracelet and the

apertures for the crown and push-buttons into the case middle and to create the

complex open surfaces, such as those of the Da Vinci Chronograph. After the

function controls, precision craftsmanship brings the surfaces up to IWC

standard. The edges are deburred and rounded off, facets are cut into the

necessary areas, all traces of turning, milling and processing are removed, and

the surfaces are fine-ground and polished, satin-finished and blasted.

Specialists now apply decorative surfaces such as circular graining to the case

or components. The case, consisting of up to sixty individual parts, is then

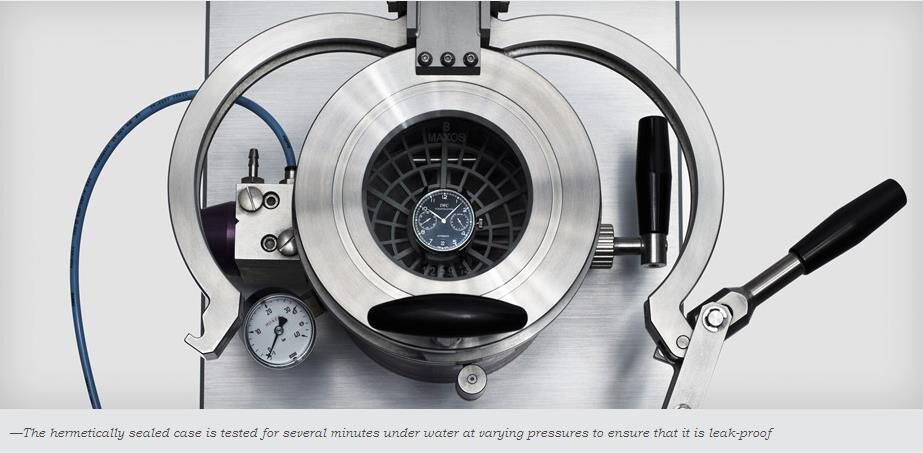

assembled. Finally, a series of complex tests such as water-resistance and

outward appearance rounds off the case production process.

In these

departments, all processes are carried out by hand. Depending on the model in

question, specialists mount the dials on the fully timed and regulated movement

by hand or using special tools. The same applies to the hands, which need to be

set at exactly the right height and grip the pivot onto which they are firmly

mounted. With chronographs, the zero position of the hands must also be

absolutely exact. The movement is secured in position either to a casing ring

or directly to the case. If the movement is gripped by a casing ring, the

latter is held in position by a wave spring in the case back. The winding stems

are individually adjusted. A special adhesive secures crowns that are screwed

onto the winding stem.

Over a

period of 10 days, the automatic movements in self-winding watches are rotated

continuously, while those with manual winding are fully wound every other day.

Running-in gives the wheels and pinions a chance to adapt to each other

perfectly, while the lubricant penetrates into all the right places.

The quality

assurance process is brought to a close with extensive final inspections. A

watchs fitness for everyday use is tested one last time by fully winding the

movement, measuring its accuracy, checking the functions and appearance, and

confirming its resistance to air and water in a series of special tests. The quality

of any product that leaves the company on the Rhine is beyond all doubt. This

seamless quality assurance process guarantees every future owner of an IWC

watch that the company rigorously upholds its legendary quality standards.

Customisation

Every watch

from IWC is already a personality with characteristics of its own.

Nevertheless, there are still customers who want more, and ask us to give their

pocket or wristwatches a touch more individuality. Thanks to modern engraving

techniques, the range of options offered by IWC in this area is virtually

unlimited. Practically any request for specific changes to personalise a watch

can be executed to perfection. Engraving comes from the French word graver

and originally meant to plough a furrow. The carving of drawings, patterns,

ornamentation or writing on wood, stone, ivory and metal creates attractive

light and shade effects and is a means of immortalising very personal ideas. At

IWC today, this age-old skill has been preserved in its original form as far as

possible. In this way, miniature works of art, such as the engravings on the

back cover of the Da Vinci Perpetual Calendar Edition Kurt Klaus or the Grande

Complication, are created for posterity. An IWC watch may also be made unique

by the addition of engraved initials, a date, a family crest, a company logo or

a personal dedication.

Service

The service

department in Schaffhausen employs around fifty people who specialise

exclusively in maintaining and repairing watches from all over the world and

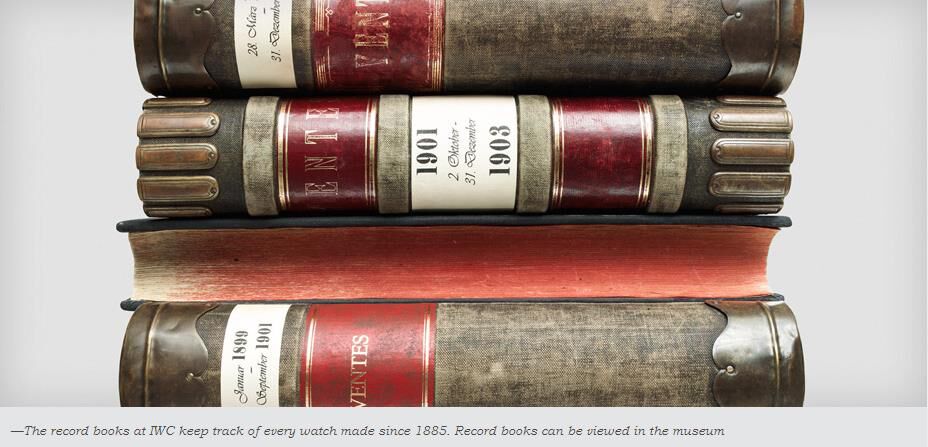

from every era since IWCs foundation back in 1868. To ensure that no single

detail is lost, IWC has maintained detailed records of every watch that has

left the factory since 1885. IWC occasionally receives models going back as far

as the first Jones calibre, and even experienced craftsmen are amazed by the

achievements of watchmakers of an earlier age. Old pocket watches accurate to

less than 3 seconds a day are no rarity.

At the

heart of the repair department is the spare parts store. This accommodates

millions of meticulously ordered individual components. Needless to say,

original replacement parts for all the companys recent models will also be

available for years to come. As a rule of thumb, a quality mechanical watch

needs a full service after about 4 to 5 years. The decisive factor is the

stresses and strains to which the watch is exposed.

- As a rule of thumb, a quality mechanical watch needs a

full service after about 4 to 5 years -

Whenever an

IWC watch returns to Schaffhausen, it is treated with the greatest possible

care. As part of every service, the watch is demagnetised and the movement

completely dismantled. Worn parts, such as wheels, pinions, springs or

bearings, are replaced. The movement is then cleaned, reassembled, lubricated

and adjusted before being secured firmly in its case. All seals and, if

necessary, the crown too are replaced. Finally, the serviced watch is subjected

to a series of intensive final checks lasting five days. Only by going to these

lengths can IWC guarantee that the watch will run accurately and remain

water-resistant for years to come.

By observing a number of simple rules, any

owner can help to give his IWC watch a longer effective service life. These

include avoiding impacts, not operating any moving parts underwater (with the

exception of divers watches) and only allowing a specialist to open the case.

- The serviced watch is subjected to a series of

intensive final checks lasting five days -

IWC

Certificate

Every watch that leaves IWC today is

registered for eternity. Since 1885, full details of the calibre, materials

used and the case number have been entered in the records. For more recent

models, these details also include the reference number. For a small fee, heirs

or subsequent buyers can obtain precise information about their IWC watch. So

far, this registration was entered into the records, which contain all the

details. From 1 July 2012, certificates will be provided for the first time. For

a certificate to be issued, the watch has to be sent to Schaffhausen, where it

is carefully and thoroughly examined by one of our experienced watchmakers. It

is not possible for a watch to be sent straight to Schaffhausen; it has to be

delivered to an authorized retailer or to an IWC boutique.

The only way to establish a watchs

authenticity is to have it examined by one of our specialists in Schaffhausen.

The information on the certificate mainly relates to the type, case and

movement. The certificate may also include information about the watchs

features. If the comprehensive examination is to reveal that a part of the

watch is not genuine, IWC reserves the right not to issue a certificate for the

watch. Unfortunately, it is not possible to provide information about the

collectors value of specific models, because this depends on factors such as

supply and demand as well as the condition of the movement and case. In the

event of a worst-case scenario involving loss or theft, it is advisable to

report the incident in writing to the police and IWC. The case number in

question is then entered in a special register, which ensures that if the watch

does turn up again, it will not go unnoticed.

- Heirs or subsequent buyers can obtain precise information

about their watches and the authorised retailer who purchased them

The Watch Aficionado

Categorie:Specials

|